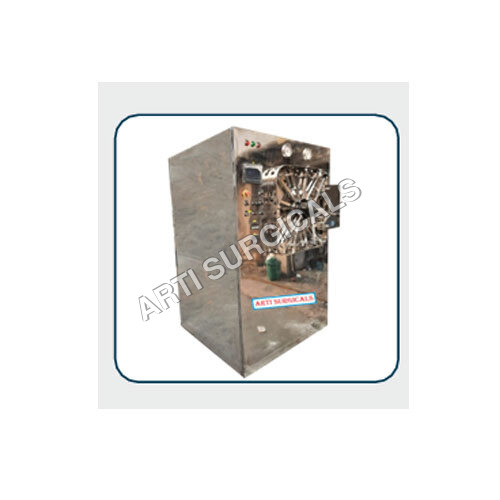

Horizontal Rectangular Autoclave

600000 INR/Gross

Product Details:

- Product Type Horizontal Rectangular Autoclave

- Power 20Kw Watt (w)

- Voltage 220 Volt (v)

- Operate Method Semi Auto

- Usage Industrial

- Material Stainless Steel

- Application Industrial

- Click to view more

X

Horizontal Rectangular Autoclave Price And Quantity

- 600000 INR/Gross

- 1 Unit

Horizontal Rectangular Autoclave Product Specifications

- Semi Auto

- Industrial

- Stainless Steel

- Silver

- Industrial

- 220 Volt (v)

- 20Kw Watt (w)

- 2.2 Kg/cm2 kgf/cm2

- Horizontal Rectangular Autoclave

Product Description

| Capacity (Ltrs) | 248 |

| Usable Size (Inch) | Dia. 20 x 48 Depth |

| Operating Temperature | 134C |

| Operating Pressure | 31 PSI (2.2 Kg/cm2) |

| Chamber MOC | SS316 (4 mm thk) |

| No. of Door | Single Door |

| Door MOC | SS304 (16 mm thk) |

| Under Pressure Door Locking System | Yes |

| Jacket MOC | SS304 (3mm thk) |

| Outer Cover MOC | SS304 (1.2mm thk) |

| Boiler Size | Dia. 12 x 14 Depth |

| Boiler MOC | SS304 (4mm thk) |

| Pipe MOC | Contact Part SS316 & Non-Contact Part SS304 |

| Frame MOC | SS304 / MS PWD |

| Control Panel | Manual/Automatic |

| Finishing | Mirror Finish |

| Total Power Consumption | 20Kw |

Durable Stainless Steel Construction

Built entirely from stainless steel, the autoclave offers excellent resistance to corrosion and wear, making it suitable for demanding industrial applications. The high-grade material enhances both longevity and hygiene, critical for effective sterilization processes.

Efficient Semi-Automatic Operation

The semi-automatic function simplifies the sterilization process, balancing precision with ease of use. Operators can initiate cycles easily, reducing manual intervention while maintaining control over key parameters such as temperature and pressure.

Industrial-Grade Performance

Operating at a pressure of 2.2 Kg/cm and utilizing 220 Volt power, this autoclave delivers swift and uniform sterilization. Its 20kW power rating ensures rapid heat generation, making it ideal for large-scale equipment sterilization in various industrial settings.

FAQs of Horizontal Rectangular Autoclave:

Q: How does the horizontal rectangular autoclave function in an industrial setting?

A: The autoclave uses steam under a working pressure of 2.2 Kg/cm and a power supply of 220 Volts to sterilize tools, garments, and other equipment. Its rectangular design facilitates the placement of large or bulky items, making it ideal for industries needing thorough decontamination.Q: What distinguishes stainless steel construction in this autoclave?

A: Stainless steel is renowned for its durability and resistance to corrosion, which is essential for maintaining hygiene during repeated sterilization cycles. This material ensures a longer lifespan and consistent performance in rigorous industrial applications.Q: When should the autoclave be operated during industrial hygiene protocols?

A: The autoclave is typically operated before and after processing batches of equipment or materials, ensuring that everything entering or exiting production is properly sterilized and free from contaminants.Q: Where can this autoclave be sourced in India?

A: The autoclave is available through various channels in India, including distributors, importers, manufacturers, suppliers, traders, and service providers. This wide network ensures accessibility and support across the country.Q: What is the process for using the semi-automatic operating method?

A: Users load the items into the chamber, set sterilization parameters, and initiate the cycle via the control system. The semi-automatic mode streamlines operations, requiring minimal manual intervention while safeguarding proper sterilization.Q: What are the main benefits of using this industrial autoclave?

A: Key advantages include efficient sterilization, robust build quality, dual voltage compatibility, straightforward operation, and reliable after-sales support from varied industry providers throughout India.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email